IN-SITU CONCRETE INSTALLATION

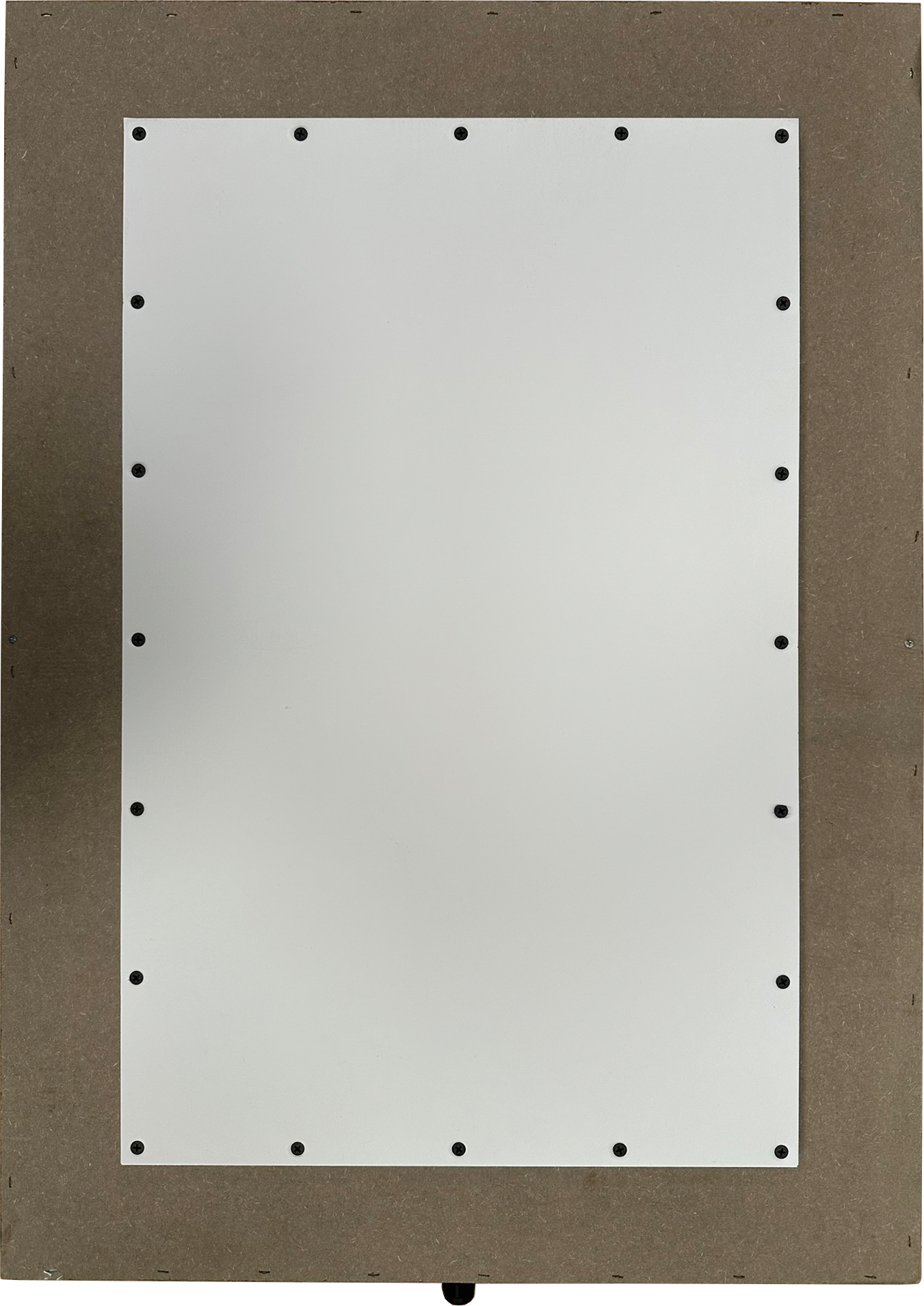

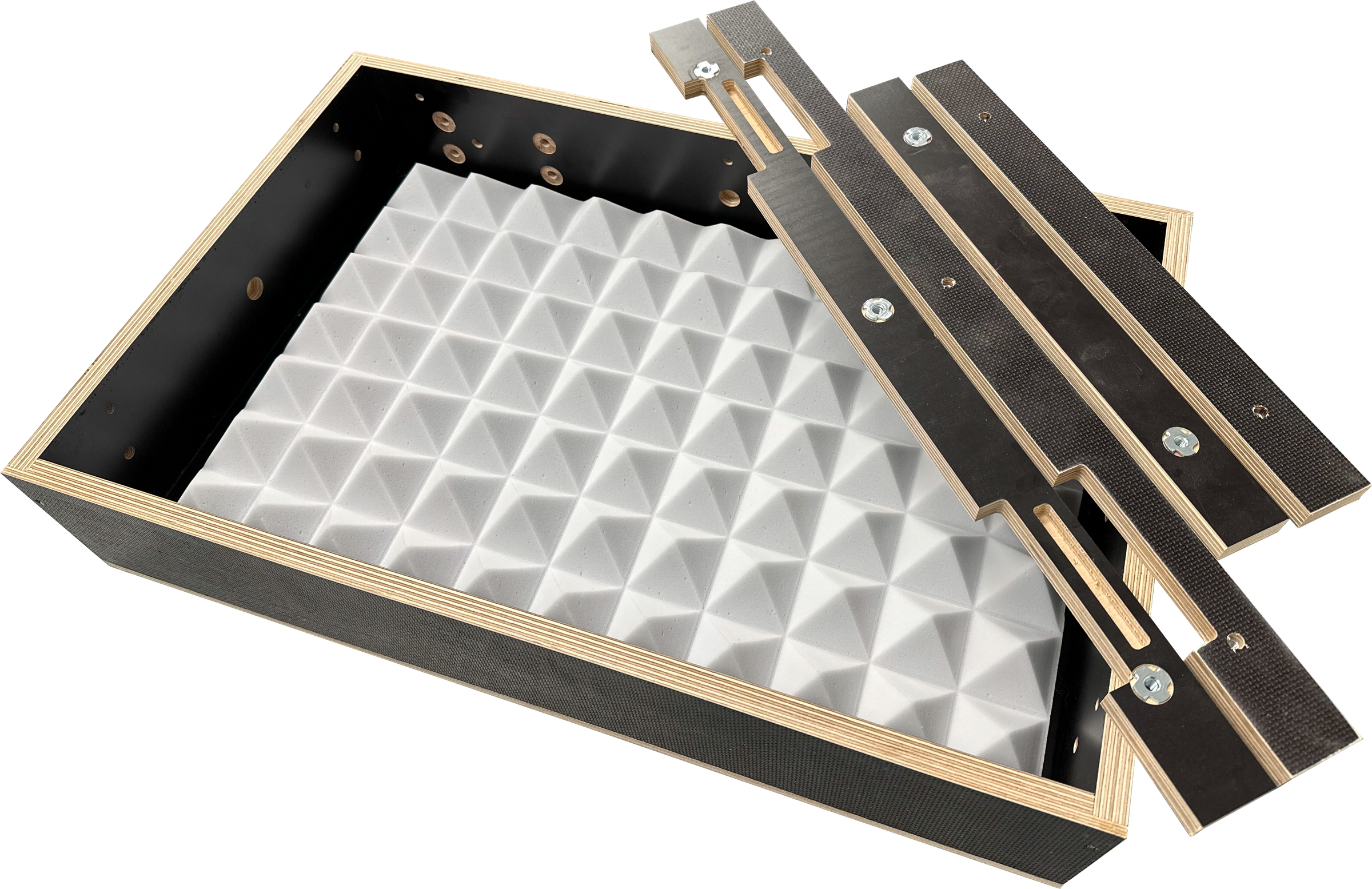

delivery content of cerasonar frame:

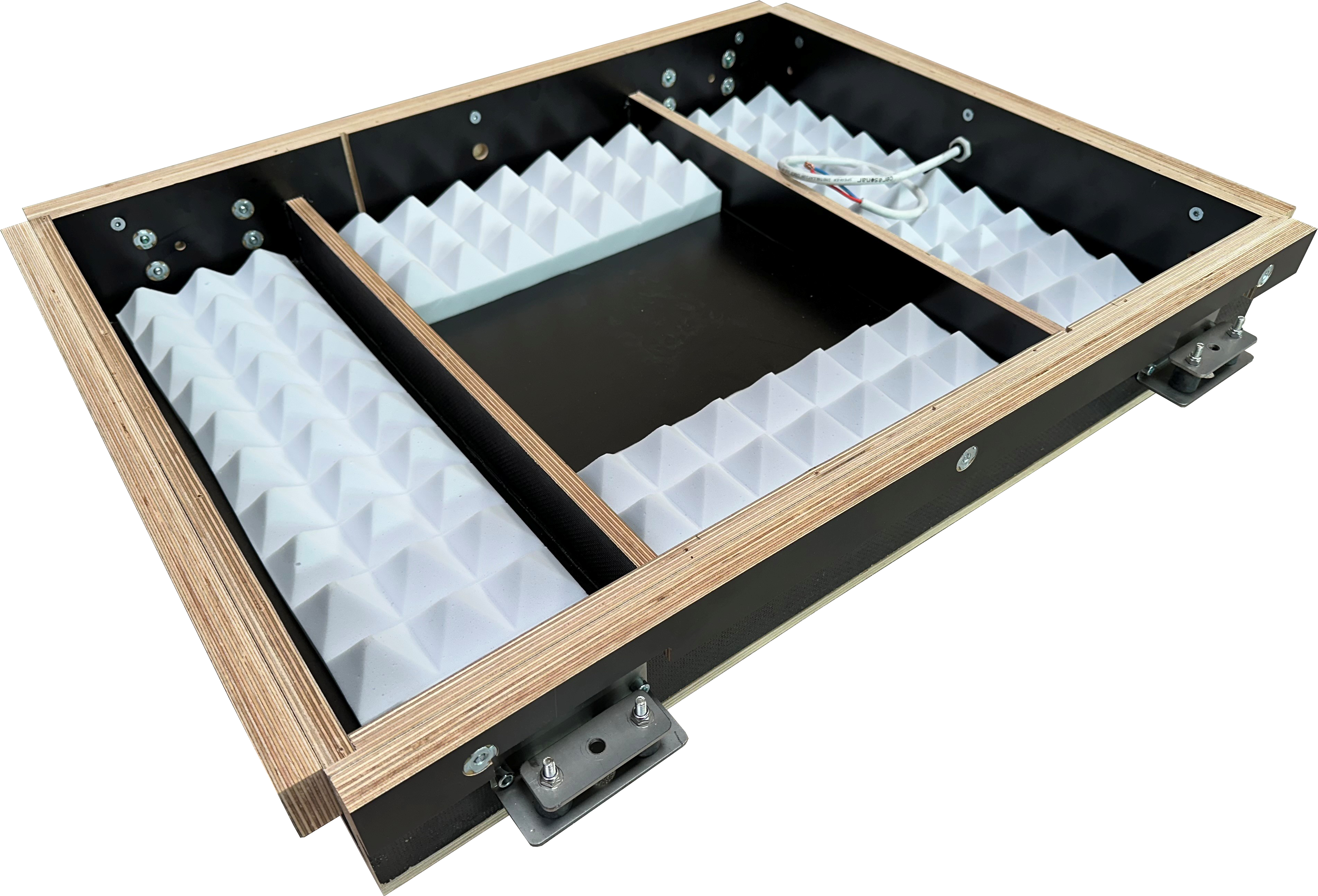

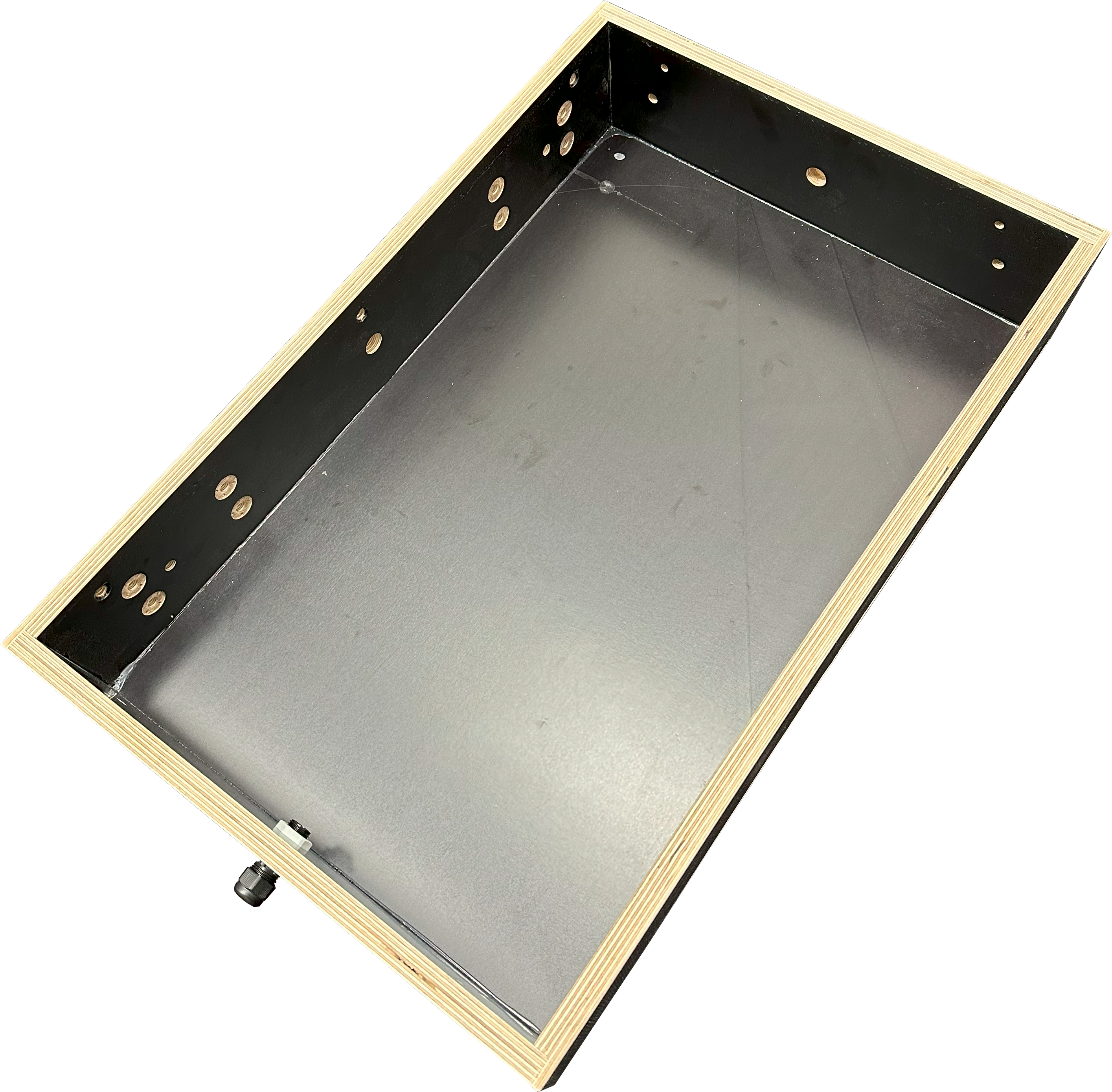

o Sturdy & waterproof glued "trailer" plywood housing

o High quality Basotect® damping material

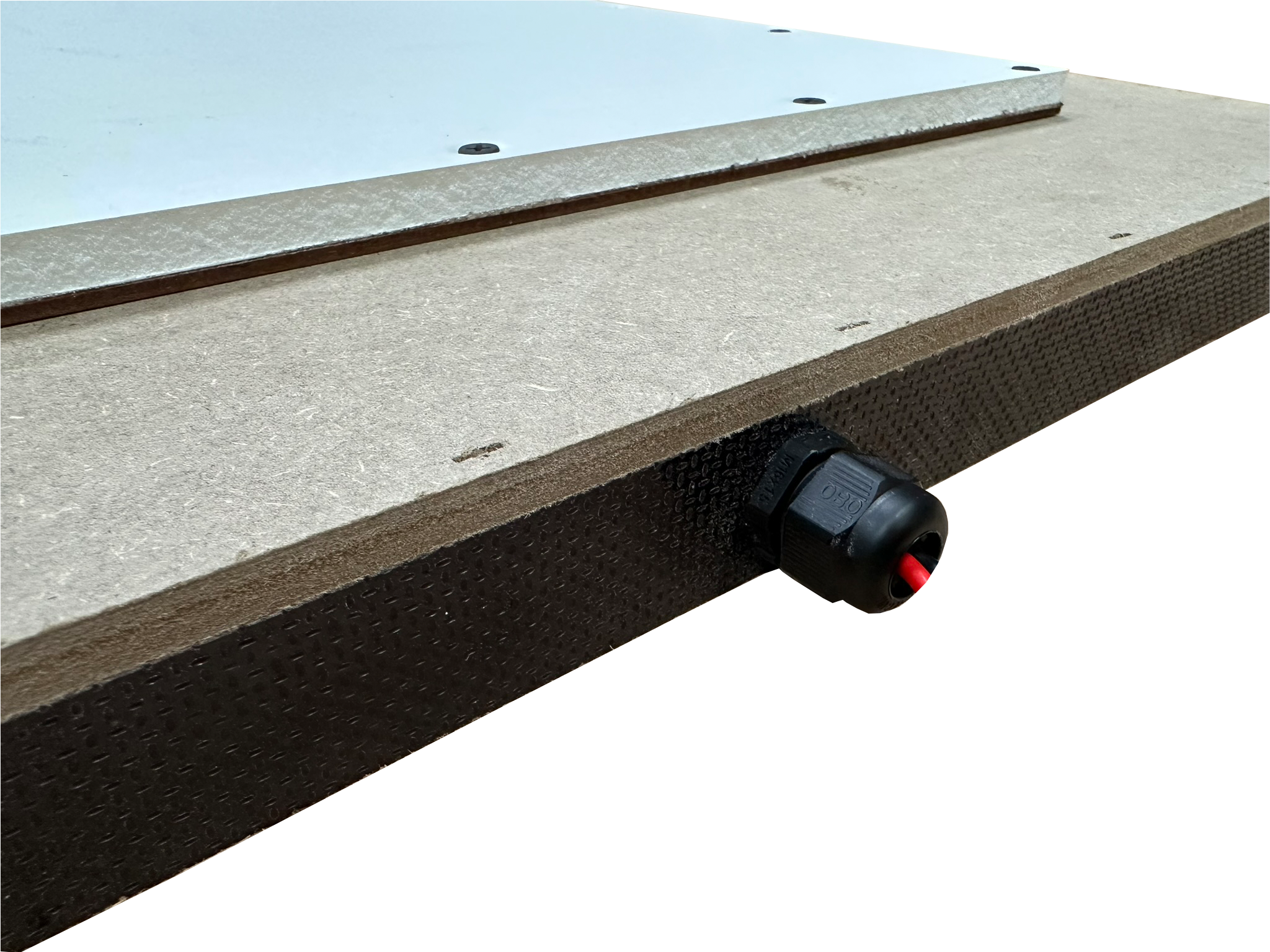

o Cable gland with integrated strain relief

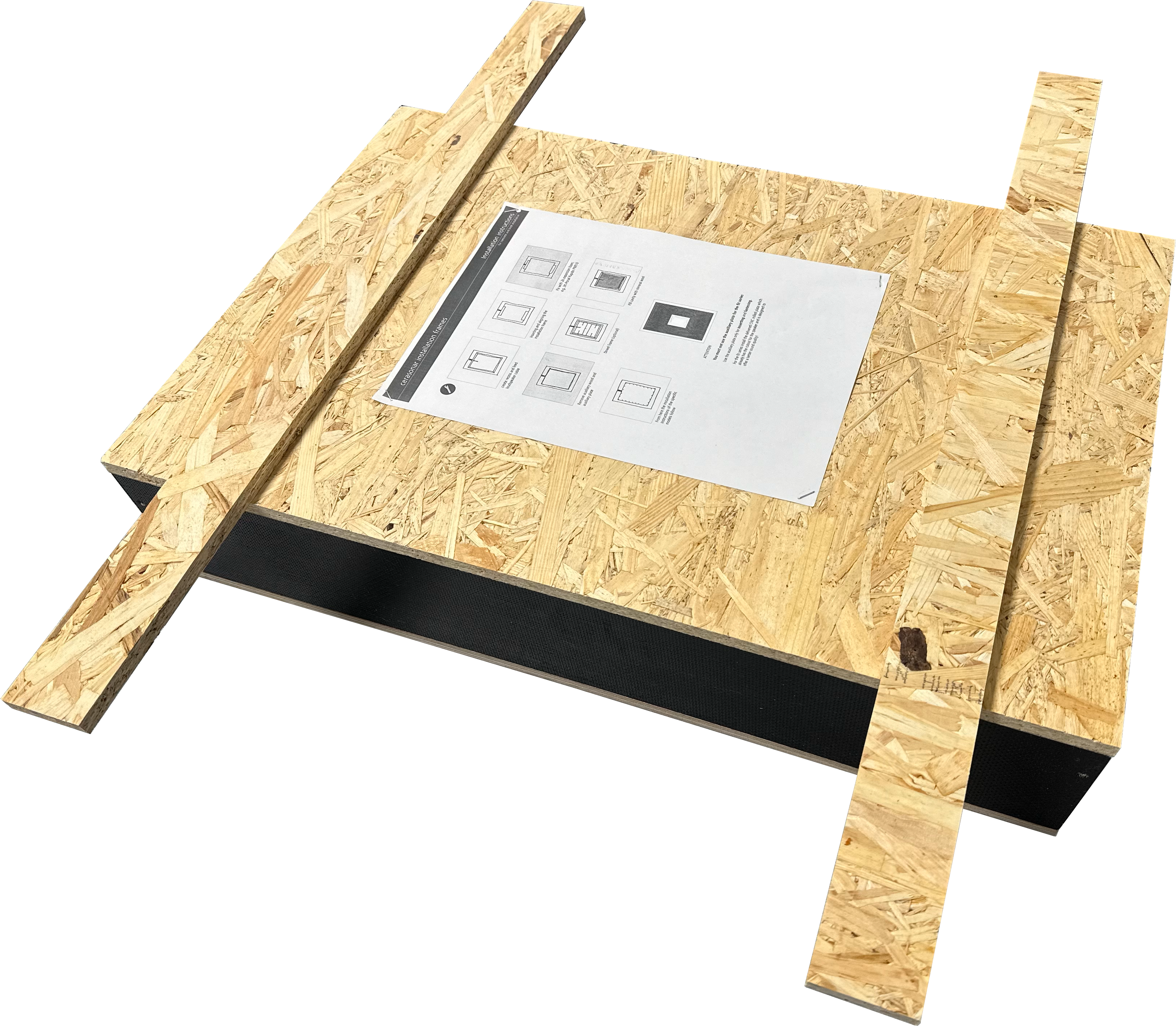

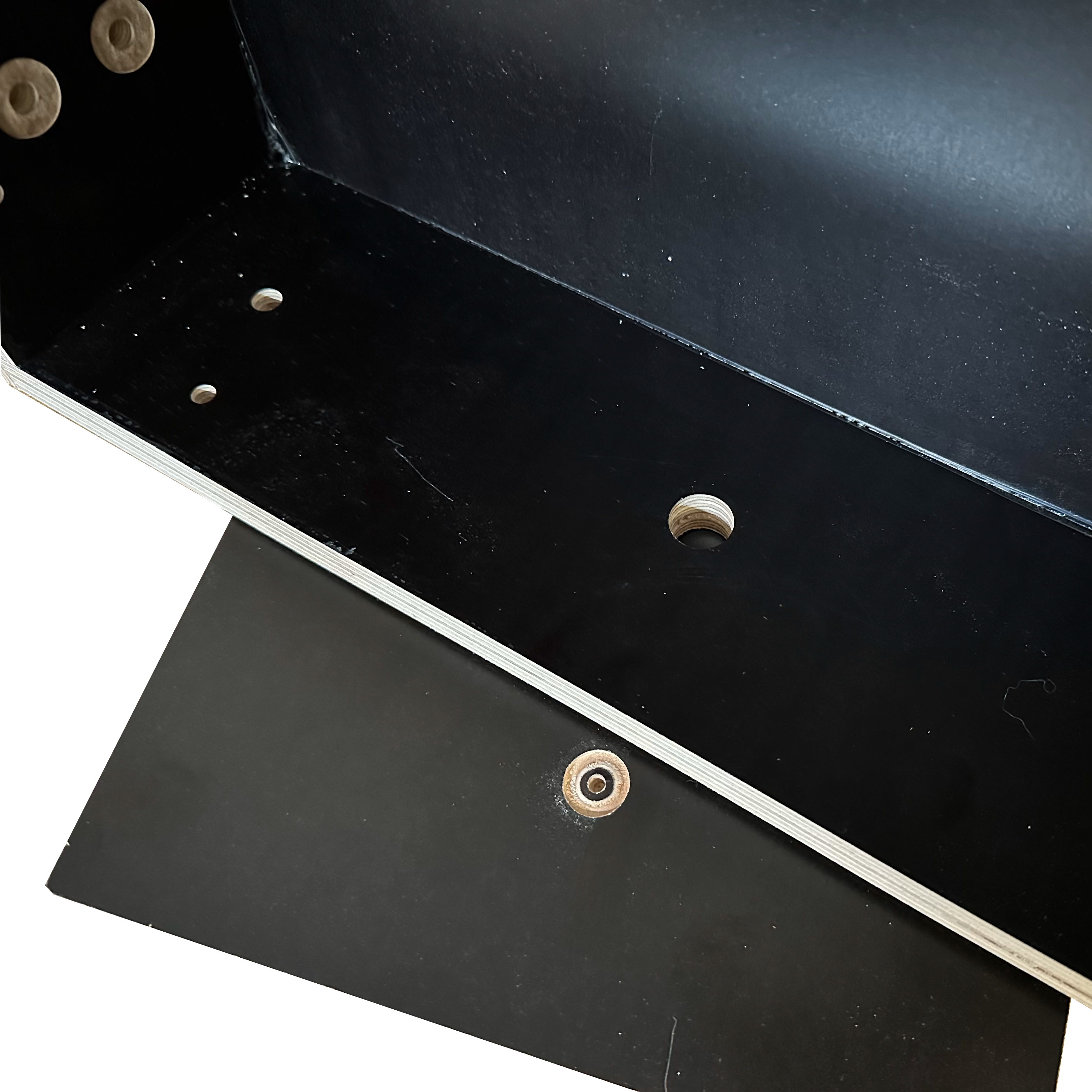

o OSB blind panel & alignment battens

o Frame comes with pre-drilled holes for easy & fast installation

In-Situ Concrete Installation:

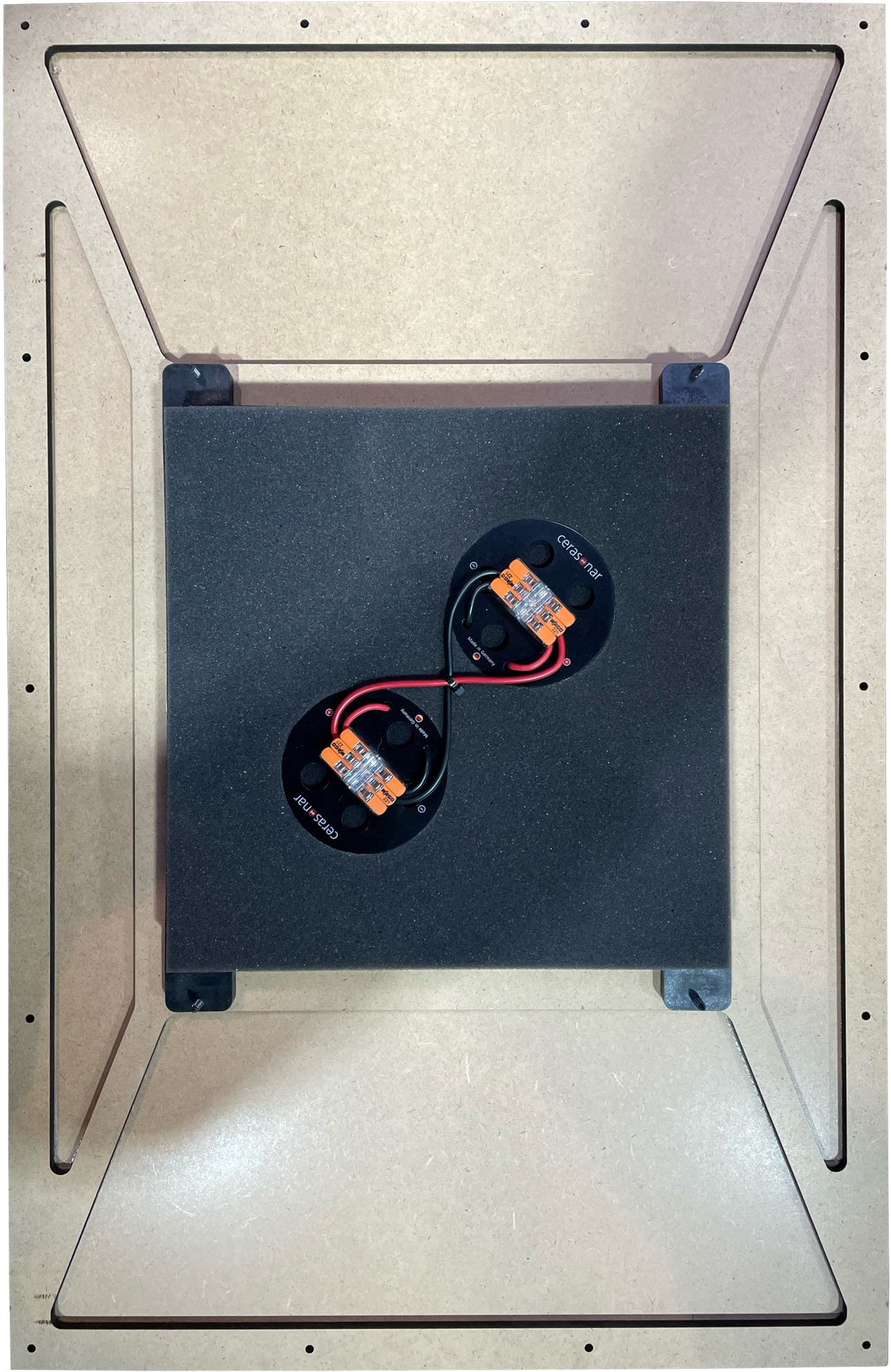

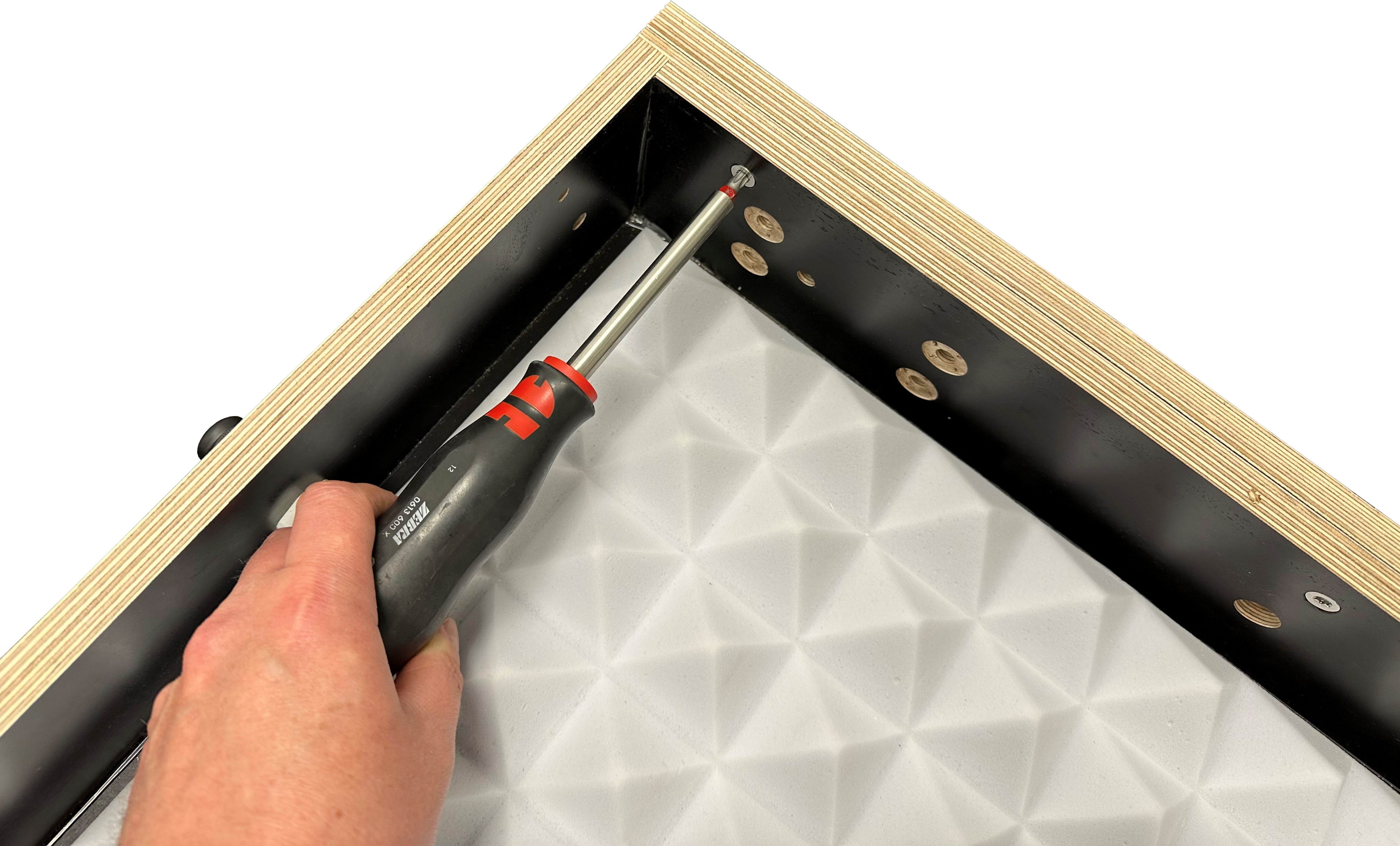

Dismantle the OSB blind panel, enlarge the cable pre-drill hole with a 16 mm drill, remove the separating film from the damping material and glue it into the installation frame, insert the OBO cable gland and tighten the nut.

Then insert the loudspeaker cable.

Place the installation frame with the reassembled OSB blind panel in the desired position on the formwork and secure it. After concreting, remove the OSB blind panel. The loudspeaker can now be installed.

TIP:

If not only the joints are to be sealed and more than 2 mm levelling compound is to be applied to the in-situ concrete ceiling, fit a thinner OSB blind panel, e.g. 9 mm, so that the maximum application thickness on the speaker of 2 mm is not exceeded.

Always use a scrap piece of wood as a base when drilling to prevent the drill edge from fraying.

Secure the OBO cable gland with the supplied nut, feed the loudspeaker cable through and secure the cable against pulling by screwing the outer black plastic cover.

After removing the formwork, remove the OSB blind panel. The loudspeaker can then be installed.

Easy and neat to use

masonry installation kit

delivery content:

- Masonry installation set consisting of:

- Frame dowels with countersunk Torx screws (8x100 mm)

- Ponal PNR10 (fast-curing, 2-component construction foam) (or similar)

Create a sufficiently dimensioned niche in the masonry, leaving enough space all round, including for the syringe of the construction foam.

Install the cable gland and damping material as described above and then refit the OSB blind panel. Screw the alignment battens to the OSB blind panel.

Now align the installation frame in the centre of the niche and fit the alignment slats to the wall.

Fill the surrounding slot with sufficient construction foam and remove the alignment slats and OSB blind panel once dry. If necessary, fit frame dowels for reinforcement. The loudspeaker can now be installed.

TIP:

If a very deep niche is available, the rear volume can be used to increase the bass reproduction. To do this, drill a hole in the rear wall of the installation frame using a large circular drill.

EASY CEILING INSTALLATION

drywall ceiling kit

delivery content:

- Drywall installation set consisting of:

- Installation battens

- Drive-in nuts

- Screws

Make a sufficiently dimensioned cut-out in the plasterboard (1-2 mm larger than the speaker), mount the long installation battens with the enclosed metric screws. Ensure that the battens are flush with the rest of the frame. Insert the installation frame into the opening at an angle.

Install the cable gland and damping material, see above.

Then fit the two short installation battens by carefully moving the installation frame in the ceiling.

Now align the housing in the centre of the opening. The screws are screwed through the plasterboard into the installation battens, one screw every 10 cm.

Structure-borne noise reduction

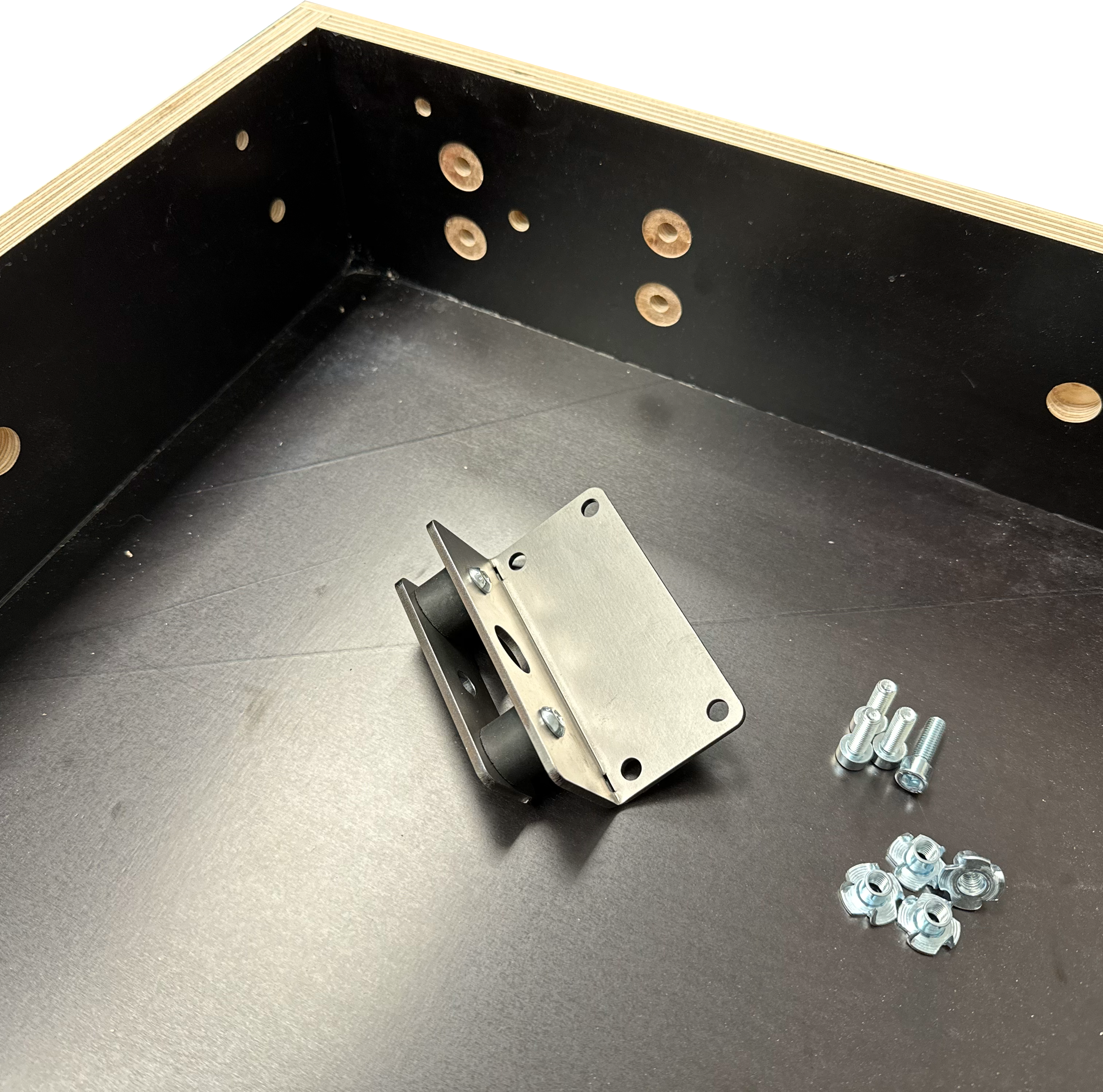

drywall ceiling anti-vibration kit

delivery content:

- Ceiling & vibration installation set consisting of:

- Installation battens

- Drive-in nuts

- Screws

- Pre-assembled dampers

Four M8 threaded rods are mounted on the ceiling. The installation height of the installation frame must then be determined. Use M8 nuts to create a limit stop and then insert the installation frame, readjust if necessary and screw in place (be sure to use screw locking!). Then fit the installation battens and screw the plasterboard to the installation battens.

Attention: Delivery without M8 threaded rods and dowels. Only suitable for ceiling installation!